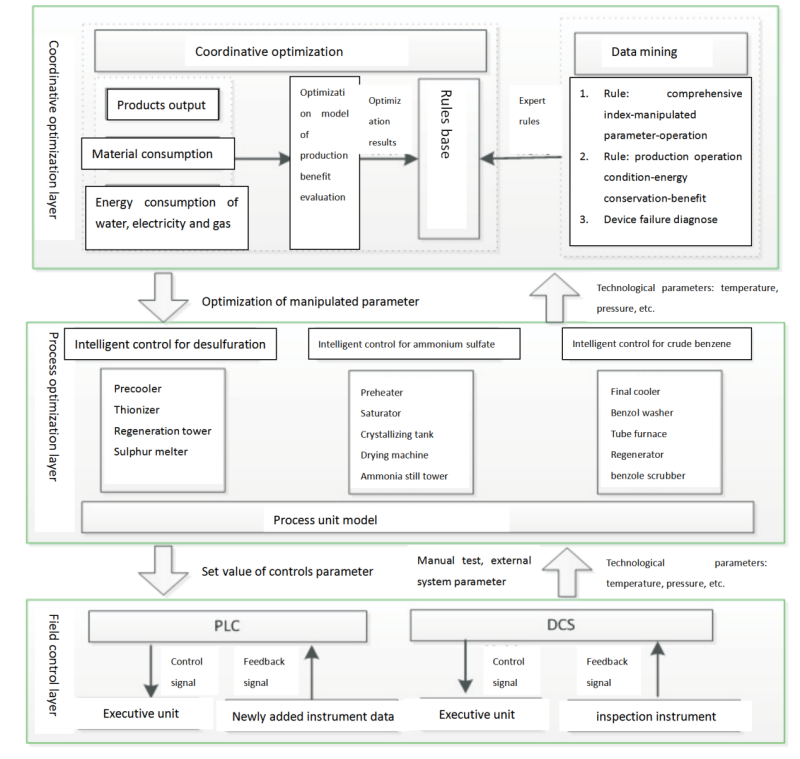

On the basis of intelligent control platform of coking integration, the system consists of desulfuration subsystem, ammonium sulfate and ammonia stilling subsystem, crude benzene subsystem, and underlying device control subsystem, which takes control of key parameters and predicts them intelligently, and provides interlocking operation and status diagnosis to underlying devices. By coordination and optimization, the system is able to take control of underlying devices and process automatically and stably ,and make top management coordination optimized , so as to improve production, reduce costs and raise the standard of management.

contact

Data collecting

collecting DCS data of device structure information, assay data and data of online analyzer.

Working conditions prediction

predict the output of raw gas, the gas components of each working section and the product output

Device character analyze

optimize the condition of device according to real-time and historical data.

Safety interlocking

Safety interlocking of device and safety interlocking in emergency: power cut, stilling cut, etc.

Optimization of technology parameter

set up production optimization model of desulfuration, ammonium sulfate, stilling ammonia and crude benzene by analyzing the relations between products output and energy consumption

Optimization of operation parameter

optimize the set value of operation parameters corrected by self-adaption through using predicting analysis, so as to reduce the fluctuation range of manipulated variables.

Visualized real-time monitoring

information parameters display of technology process, interlock warning display of technological parameter, safety parameter and video device.

Auxiliary function

include data management, information sharing, system settings, system malfunction diagnose, warning, log management, etc.Firstly, the system integrates coking process and gas collecting process, from the angle of material conservation, energy conservation and the theory of gaseous phase and liquid phase mass transfer and separation, the system analyzes the mechanism of desulfuration, deaminization, ammonia stilling and debenzolization process, establishes models of absorption process, distillation process, heat transfer process and reactivation process, and feeds controls parameters forwardly.

Lastly, builds model of production benefit optimization by establishing relation between production and material conservation and energy conservation, so as to optimize the key technological parameters of production. Meanwhile the system analyzes historical data and relates to rules of “production index, state parameter, operation index “ and rules of working condition evaluation by mining history data, and constantly improves rule base by self-learning rules.

copyright Hunan Qianmeng Industrial Intelligent System address:28 Kangwang Industrial Park, Yueyang record number:湘ICP備20000218號-1business license

Technical Support:Competition network