As an important link of bulk material industrial production supply, material distributing plays an indispensible role in production, and in the process of material distributing, accuracy of material storage and discharge poses great influences on the quality of finished products. In present industrial model, many companies, who still relying on manual work and experiences work, are intensively labored and unable to control its accuracy; when unqualified product occurs, root cause of accidents cannot be traced given low-level automation, thus the quality of products cannot be improved for a very long time.。

contact

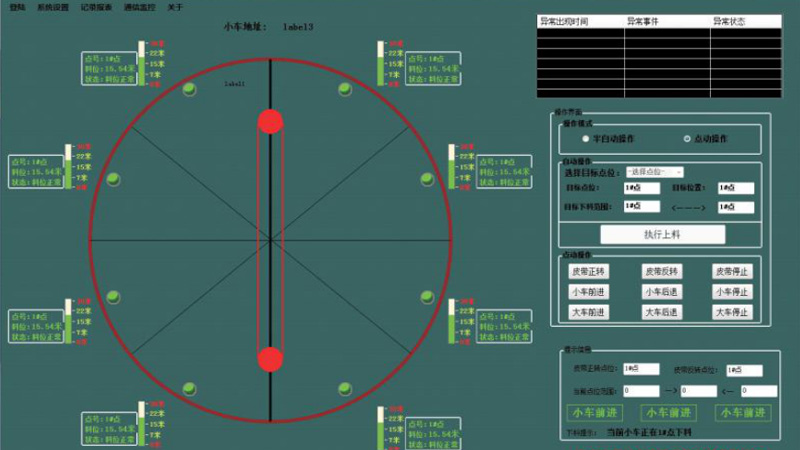

Each actual position of the conveyor car in the material yard has a unique address in the system which is one-to-one correspondence, the accuracy is 2mm.

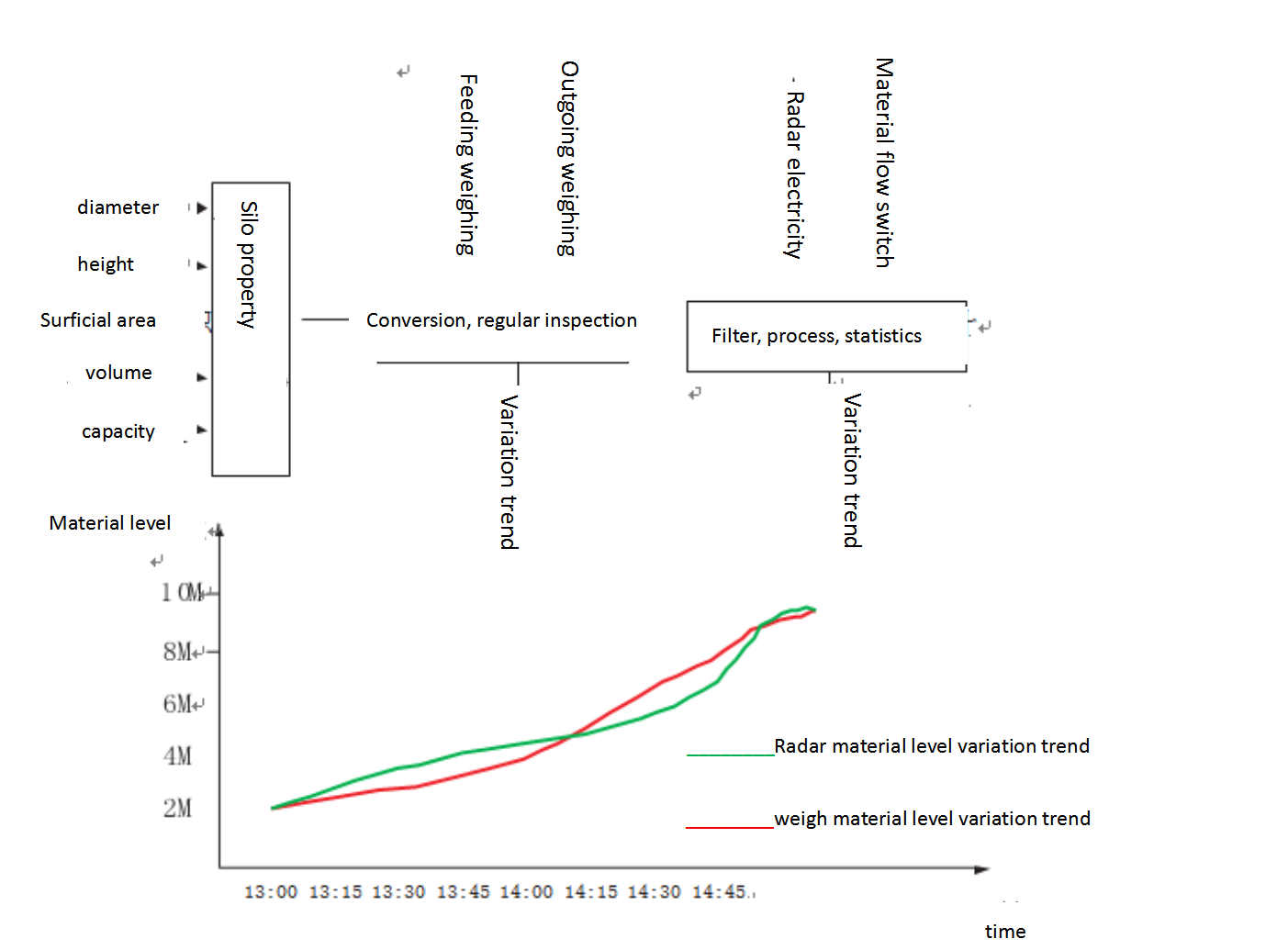

multiple backup material level algorithms assist radar material level data detecting, so as to ensure the continuity and accuracy of material level.

access to material-loading schedule; make material-loading schedule manually according to actual situation; real time genarate material-loading schedule automatically.

real time recording of actual production automatically in form of logs and report forms: blanking records, mannual operation records, equipment movements logs

set break value, position value of storehouse

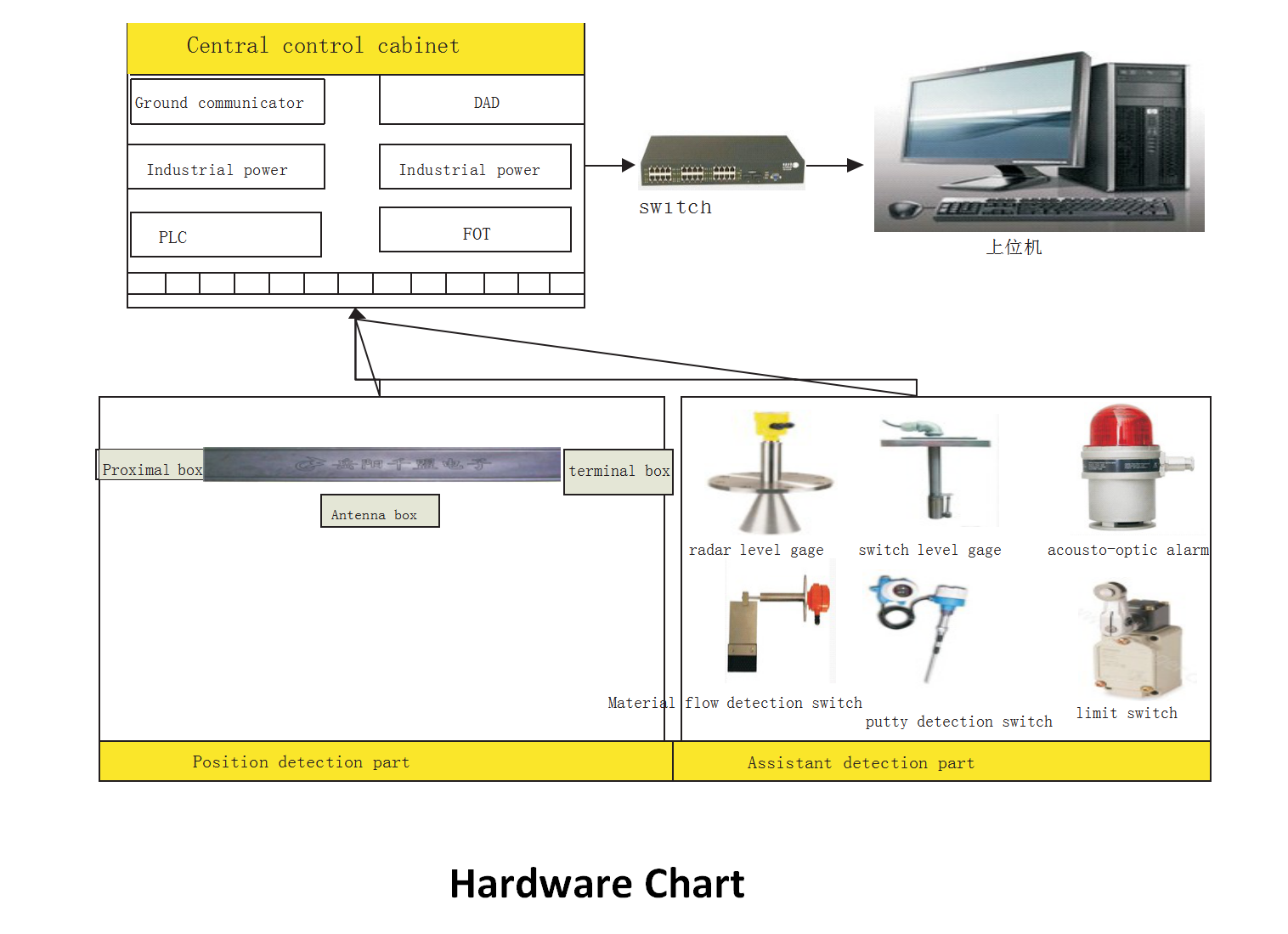

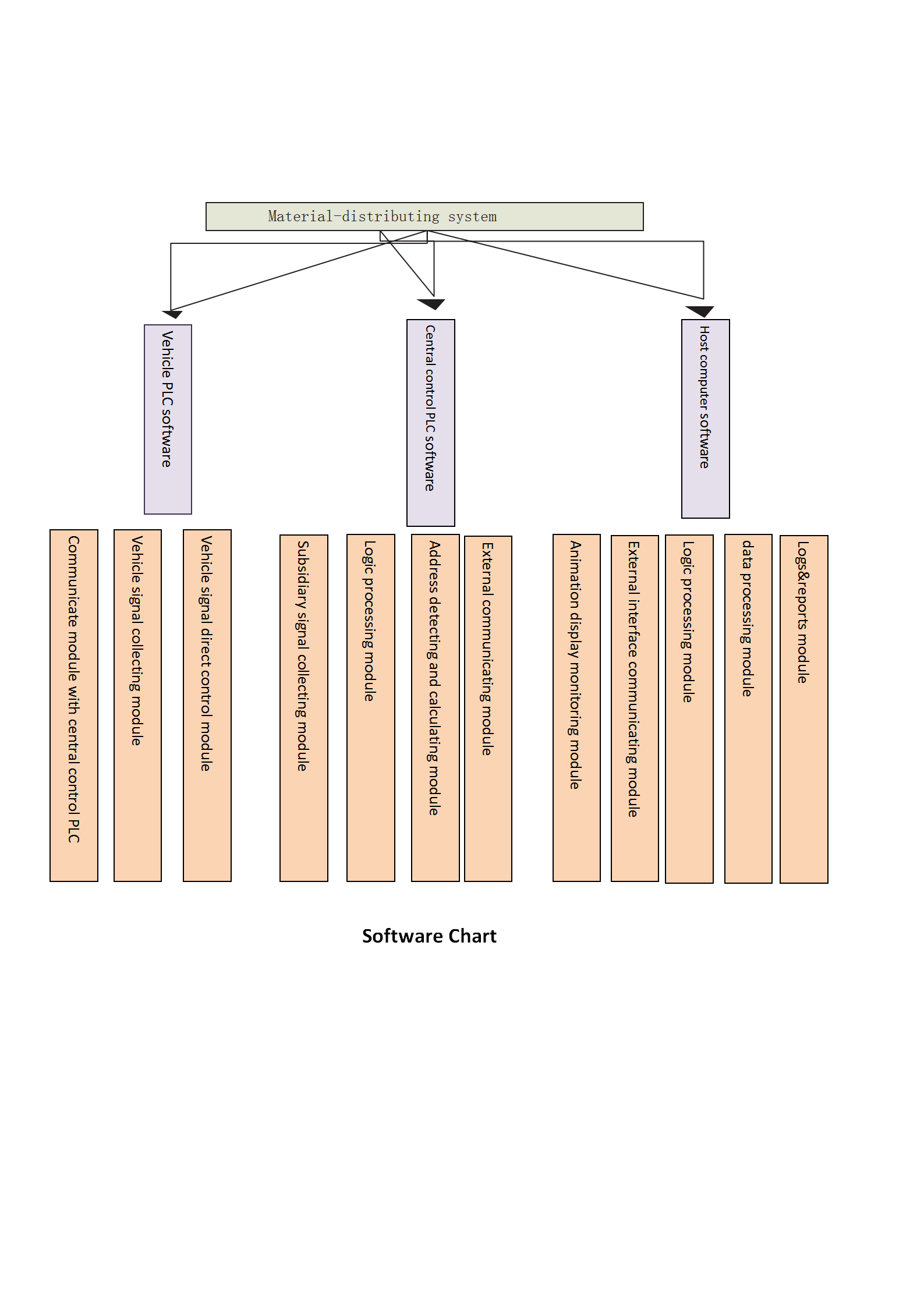

Structure

Through equipment status monitoring, stock yard intelligent management and operation intelligent scheduling, stock yard intelligent scheduling management system can manage elaborately product information from the whole process, push forward stock yard production more intelligent and informationized, so as to reduce labor intensity and cost of operators

Through equipment status monitoring, stock yard intelligent management and operation intelligent scheduling, stock yard intelligent scheduling management system can manage elaborately product information from the whole process, push forward stock yard production more intelligent and informationized, so as to reduce labor intensity and cost of operators

copyright Hunan Qianmeng Industrial Intelligent System address:28 Kangwang Industrial Park, Yueyang record number:湘ICP備20000218號-1business license

Technical Support:Competition network